Within SSOE, we’ve identified four fundamental enablers of VDC—essential elements to have in place for truly successful implementation of VDC project delivery.

#1: Information capture (laser scanning) – for an accurate picture of current conditions. 3D laser scanning is the fastest, most efficient method to capture existing conditions of many facilities or sites. This replaces the time consuming and less accurate method of manually recorded field measurements. Now, lasers scan an existing facility or site creating a point cloud that acts as a highly accurate as-built drawing. The point cloud can be referenced into a 3D model to avoid collisions with the proposed design and costly rework in the field—resulting in an incredibly realistic and detailed 3D model of an existing facility.

#2: Coding structure for models – to allow data mining to automate and enhance certain functions, like quantity take-offs for estimating. This requires each model element have a unique code, and also that coding is consistently used from the very onset of a project. This concept encourages a more holistic approach to project delivery by leveraging data embedded in the models to improve and optimize other project efforts such as estimating, quality assurance, safety, documented savings, and more.

#3: Internal integration of the model – the ability to integrate design efforts between disciplines; one example is conducting multi-discipline reviews within the 3D model. SSOE’s 3D design review sessions bring together discipline leads before a client coordination meeting to hash out the agenda for the next meeting with project stakeholders. The agenda is a critical component in driving coordination success and serves as a framework to identify specific issues that need to be addressed during the meeting to move the project forward. One key benefit is that the internal review engages the design leaders by getting them into the model to find, track, and proactively resolve issues, as opposed to simply reviewing drawings prior to the meeting. Issues that require resolution or decisions from the client are captured within the model, and any later input from project stakeholders is added to keep a visual record of changes.

#4: External model collaboration during the execution of the project – the processes and technology required to gather input and create alignment with the fabricators, trades, and contractors into the model during construction. Methods to facilitate this collaboration, such as Interactive Planning (IAP) sessions, are also essential, even before the development of the model.

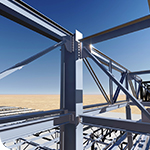

Coordination within the model takes place as various trade partners enter routing and fabrication-level detail (including hangers, supplemental supports, etc.) into their trade models which are used to generate submittal drawings for approval. These individual models are brought into one coordination model to uncover conflicts and avoid costly issues in the field that would otherwise be missed. For example, on one project, once detailed models of the fire suppression systems and mechanical systems were put into the coordination model, it was discovered that there wasn’t enough clearance around the fire suppression system and the mechanical system design was adjusted prior to construction.

Performing external model coordination does for the entire construction project what internal model integration does for cross-discipline coordination. It highlights interferences, provides one “source of truth” for making adjustments, and drives the discussion and collaboration needed between partners to improve project outcomes so the owner knows exactly what will be built in the field.

Return to SSOE’s VDC Blog page >>