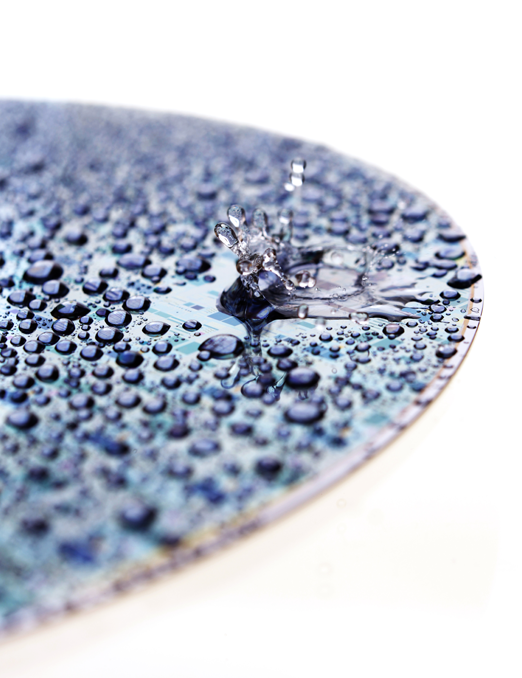

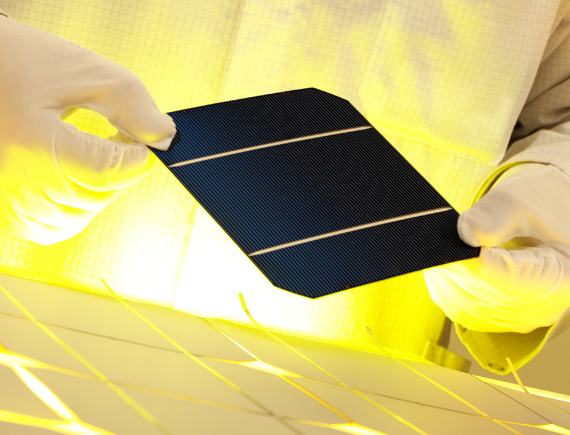

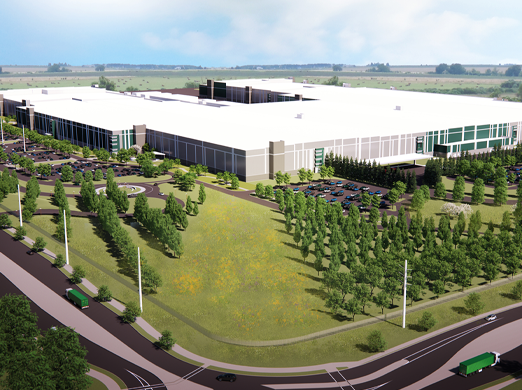

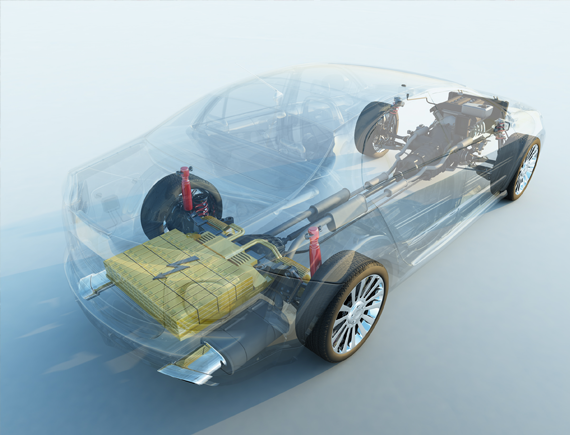

NPA Coatings Inc. (NPAC), a manufacturer of chemical coating products, purchased a 45 acre re-purposed brownfield site from the city of Chattanooga, Tennessee to build a new facility to manufacture e-coat, acrylic resins, and paint for the automotive industry.

SSOE was selected to provide an Engineering, Procurement, and Construction (EPC) delivery method using a technically-led open book approach. NPAC is fully integrated in all activity, design reviews, procurement, and construction while SSOE offers a single point of responsibility – consistent project leadership from FEL to commissioning. Construction planning began from the project start, which prevents delays in the process install due to site construction and early site / structure packages, while eliminating waste and hidden costs in design hand-off to procurement, fabrication, and installation. Because of the all-encompassing scope of this project, SSOE drew from its extensive bench of engineers and architects from our chemical, facilities, and construction management groups to form an experienced team to work closely with NPAC.

An EPC open book strategy gives SSOE full project responsibility from FEL to commissioning, using one contract between SSOE and NPAC to cover the entire project. SSOE will bid and award hundreds of pieces of equipment and construction contracts, while NPAC will be fully involved in the decision making process and review of all quotations. A target budget will be prepared following the FEL work with a recommended contingency agreed by both SSOE and NPAC, ultimately leading to a reduction of the budget to offset overall risk.

The design includes translation from international practices to U.S. standards, for full safety and environmental compliance, including support for VOC / HAP emissions estimates, building classification evaluation, and storage for chemical compatibility hazardous materials storage, possible flood plain siting issues, and building height constraints within a nearby FAA regulated flight path.

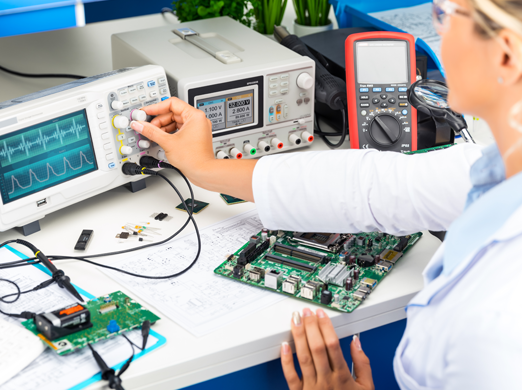

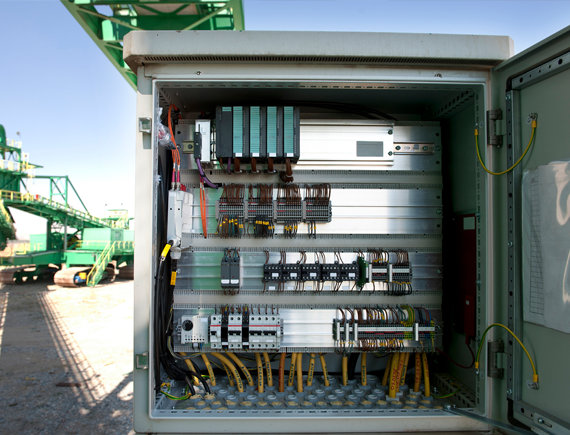

SSOE is performing substantial FEL design to address all major code and safety considerations and resolve multiple design variables to define and provide cost certainty to the facility scope and enable funding approval by the parent company board in Asia. Based on the strength of that design process, NPAC will be able to evaluate and include substantial process controls upgrades in the design basis which will substantially improve product consistency, product quality, and employee safety.

Related to the building envelope, in addition to architectural design, SSOE’s facilities team is providing civil, structural, mechanical, and electrical engineering including fire protection services. NPAC hopes to achieve LEED status for the project and design is ongoing in accordance with pursuit of LEED certification.

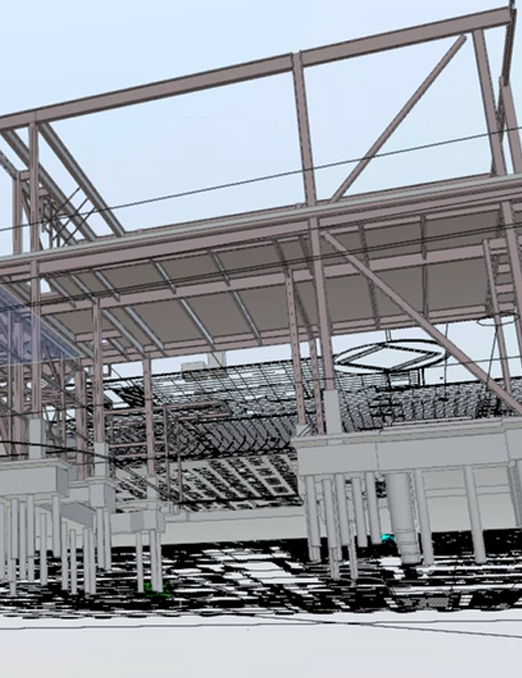

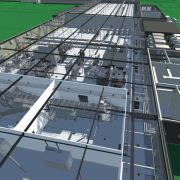

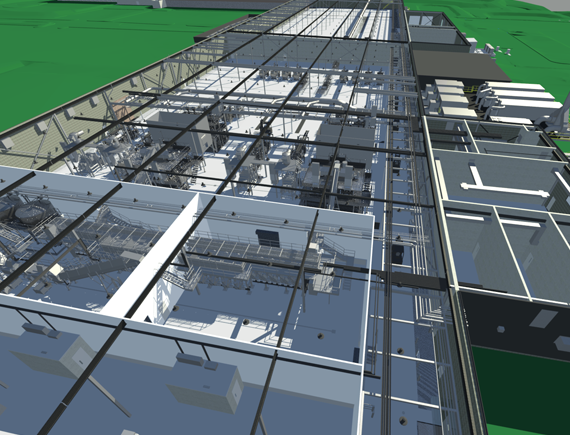

Streamlining steel package delivery with BIM2Fab® Steel

To meet the aggressive project schedule, SSOE plans to leverage our BIM2Fab Steel services, an innovative application of virtual design technology that seamlessly integrates steel design and fabrication to deliver exceptional quality. BIM2Fab Steel offers multiple advantages, from minimized risk to reduced cost and schedule—in this case, compressing the schedule by at least 4 weeks and saving NPAC time, trouble, and money in the process. Our BIM2Fab Steel models save weeks on construction schedules and can be used for clash detection and coordination across trades, ensuring a cleaner, better delivered finished product.

In close collaboration with the client and steel fabricators, SSOE’s BIM2Fab Steel team can release fabrication-ready drawings just days, as opposed to weeks, after design documents are released. SSOE will supply detail and erection sheets as well as CNC files for automated fabrication machines, further cutting down the time required to deliver structural members to the field.